Did you know that the industrial packaging market size is expected to reach $83.45 billion by 2029?

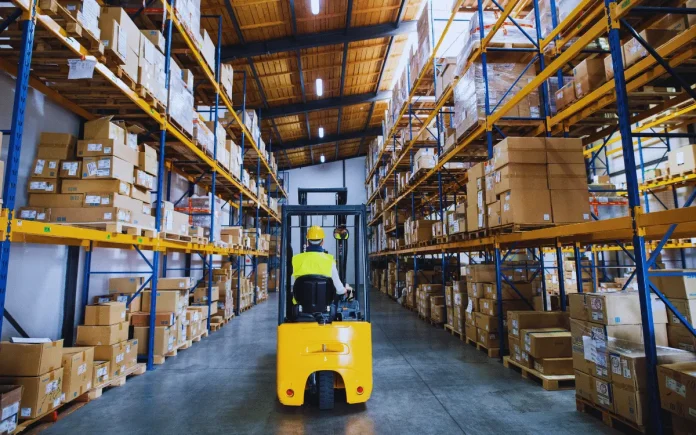

Industrial packaging is the material used for protecting, storing, and transporting goods. They are essential in ensuring the safe delivery of products. They come in various types to cater to the different needs of industries.

In this article, we will discuss the different types of industrial packaging materials and their uses. This will help you choose the right packaging material for your business needs. Continue reading to learn more.

Corrugated Boxes

Corrugated boxes are one of the most used packaging materials. They’re made of corrugated cardboard, which is lightweight and durable. This makes it suitable for a wide range of products.

These boxes come in different sizes and shapes. This makes them versatile for various industries. They’re used for:

- Shipping

- Storage

- Display

- Protecting fragile items

- Food packaging

These boxes are also environmentally friendly as they can be recycled. They also allow for customization with printing or labeling for branding purposes. This makes them an effective tool for marketing.

Plastic Packaging

The use of this packaging in the industrial sector is due to its versatility and durability. It comes in various forms such as:

- Plastic bags

- Films

- Containers

- Bottles

- Trays

Plastic packaging is ideal for protecting products from moisture and dirt during transportation. It is also lightweight, making it cost-effective for shipping purposes.

However, the use of plastic packaging has become a concern for its impact on the environment. As a solution, many companies are now using biodegradable and recyclable plastics. This is to reduce their carbon footprint.

Metal Packaging

Metal packaging is commonly used for heavy-duty items that require strong protection. It’s made of materials such as aluminum, steel, or tinplate.

This type of packaging provides excellent strength and durability. This makes it ideal for long-distance transportation. It also protects products from external factors such as moisture, light, and heat.

Metal packaging uses include:

- Food and beverage products

- Chemicals and hazardous materials

- Industrial equipment and machinery

- Automotive parts

However, it can be costly compared to other types of industrial packaging materials. Its weight and size also make it less efficient for shipping large quantities.

Wood Packaging

Wood packaging is used for heavy or bulky items that need sturdy protection. This includes crates, pallets, and wooden boxes.

Wooden packaging is ideal for industries such as construction, agriculture, and mining. It provides excellent strength and protection for heavy items during transportation. It is also cost-effective and can be reused multiple times.

Glass Packaging

Glass packaging has non-reactive quality. This makes it perfect for the food and pharmaceutical industries.

It offers excellent protection against contamination. It also does not degrade or leach chemicals into the product it houses.

Glass can be recycled without losing its purity or quality. This makes it an environmentally friendly option. However, its fragility and weight add to transportation costs and risk of damage.

Hexacomb Packaging

Hexacomb packaging is a type of honeycomb paperboard material. It offers excellent cushioning and protection for fragile items. It is lightweight, recyclable, and customizable to fit various product shapes.

It is commonly used in industries such as electronics, automotive, and furniture. Its unique design also allows for efficient use of space during storage and shipping.

Flexible Packaging

Flexible packaging refers to any package whose shape can be readily changed using non-rigid materials. This includes pouches, bags, envelopes, and wraps. They’re made from materials like films, foils, or coated paper.

It’s used in the food, pharmaceutical, and consumer goods industries. The adaptability of flexible packaging allows for innovative designs and functionalities. This includes resealable closures and stand-up pouches.

Foam Packaging

Foam packaging is used for its excellent shock absorption qualities. This type of packaging is particularly beneficial for:

- Electronics

- Glass items

- Sensitive medical equipment

- Fragile products

Materials like polyethylene and polyurethane foams are common. They provide various densities and protection levels per specific product requirements.

Foam packaging can be custom-shaped to fit any item. This ensures protection against impact, vibration, and temperature fluctuation.

Textile Packaging

Textile packaging involves the use of various fabrics like cotton and non-woven materials. This is to protect and wrap products. It is commonly used for wrapping industrial parts.

Textile packaging is valued for its durability, reusability, and biodegradability. It offers excellent protection against scratches and dents.

However, it may not be suitable for long-distance transportation. It can get damaged if exposed to moisture or rough handling.

Vacuum Packaging

Vacuum packaging removes air around a product before sealing the package. Typically used in the food industry, it extends the shelf life of perishables. It inhibits the growth of bacteria and mold.

Vacuum packaging is also used for medical and pharmaceutical products to maintain sterility. The vacuum pack’s tight wrap ensures the shape of the content is maintained. It also provides efficient use of space during transport and storage.

Insulated Packaging

Insulated packaging is crucial for temperature-sensitive products. This can include foods, pharmaceuticals, and chemicals.

This type of packaging is designed to maintain a consistent temperature. This helps protect the contents from extreme heat or cold.

Materials used for insulated packaging include polystyrene and reflective aluminum foils. Insulated packaging is essential for maintaining product quality during transport and storage. It also helps reduce spoilage and returns due to damaged goods.

Electronic Packaging

Electronic packaging is specifically designed to protect electronic components and devices. It offers protection from static and electromagnetic interference during transportation and storage.

Materials like anti-static bags, conductive foam, and shielded containers are used. This is to ensure the safety and integrity of electronic items. This packaging is crucial for the consumer electronics, aerospace, and automotive industries.

Exploring the Diverse World of Industrial Packaging

Choosing the right industrial packaging material is crucial for protecting and transporting goods. Each type has its unique features and benefits that cater to different industry needs.

Remember to also comply with any regulations related to your specific industry. With the right packaging, you can ensure the safe delivery of your products. it can also enhance brand image through effective marketing.

Do you love reading informative content like this? If you do, then you’re in the right place. Keep browsing through our blog to find more interesting content!

FURTHER READING