In modern logistics, efficient delivery of goods ensures seamless business operations. One indispensable element of this process is pallets – indispensable aids in transporting various cargoes. From simple structures to complex inventory management systems, pallet shipping remains a fundamental tool for effectively organizing warehouse operations and logistical processes.

Pallets and Their Role in Cargo Transport

They play a crucial role in cargo transport and are an integral part of the logistical infrastructure in many industrial sectors. They are flat platforms, typically made of wood, plastic, or metal, for packing, storing, and transporting goods.

Pallets in Logistics:

1. They provide a uniform standard of size and shape, allowing for efficient loading and unloading of cargoes using forklifts and other equipment.

2. They protect goods from damage during transportation.

3. They help optimize the use of space in cargo compartments of vehicles.

Types of Pallets

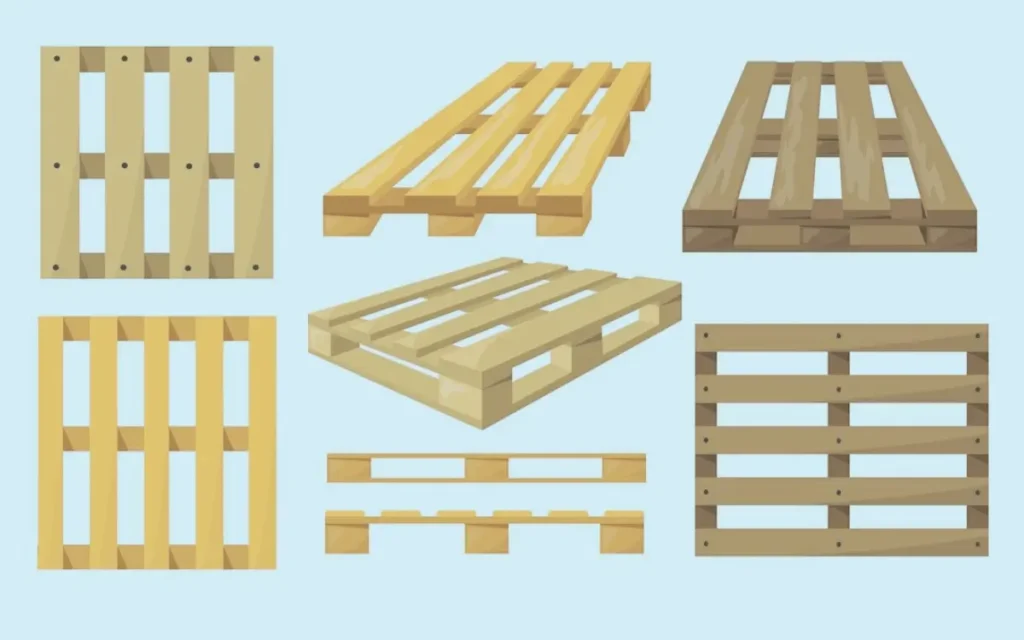

There are several types, each with its own characteristics and applications, depending on the specific needs and requirements of the logistical chain.

Here are some of the most common types:

Euro Pallets (EUR). These are widely used in Europe and have standard dimensions of 1200 mm × 800 mm. Usually made of wood, they are known for their strength and durability. They serve as the standard for many industries, such as food and retail.

Standard Pallets (ISO). With dimensions of 1200 mm × 1000 mm, these are the international standard in logistics. They are most common in North American and Asian countries and can be made of various materials, including wood, plastic, and metal.

Lightweight Pallets. Typically used for light cargoes or when weight savings are crucial for reducing transportation costs. They can be made of plastic or composite materials and have relatively low weight.

One-way Pallets. Often made of cheap materials like cardboard or lightweight wood, these are designed for one-time use. They are typically used when there’s no need to return them after cargo delivery.

Non-standard Pallets. Depending on specific transportation requirements and product characteristics, other types, such as frames, boxes, and others, may be used.

Choosing the appropriate type depends on various factors, including types of goods, transportation methods, logistical requirements, and budget constraints. It’s important to consider these factors when selecting them to optimize logistical processes and reduce costs.

Methods of Transport

Several methods of transport can be selected depending on specific needs and transportation conditions.

Forklifts

One of the most common and efficient methods of moving them in warehouses or cargo spaces. Forklifts are used to lift and move pallets using specialized forks, enabling quick and safe loading and unloading of cargo.

Manual Trolleys

Manual trolleys or hand trucks can also be used to move them over short distances. This method is particularly useful when access is limited or when cargoes are moved within spaces with limited room.

Side-loading Forklifts

This type of forklift provides easier access, especially in tight warehouse conditions or when transporting in narrow corridors. Side-loading forklifts can be particularly effective when dealing with long or non-standard sizes.

Automated Systems

In some cases, automated systems such as conveyors, robotic forklifts, or automatic warehouse systems can be used for transport. These systems can provide a high degree of efficiency and automation in logistical processes.

Interstate and International Transport

For long-distance transport, they can be carried using various modes of transportation, including trucks, railway cars, containers, and even maritime vessels. In such cases, pallets are usually secured to the cargo using straps or specialized fastening devices.

The Importance of Proper Pallet Packaging

The importance of proper packaging cannot be underestimated in the context of efficient and safe cargo transportation. Proper packaging ensures the protection of goods from damage, optimization of space utilization, and efficiency of logistical processes.

Here’s why it’s so crucial:

Cargo Protection

Proper packaging helps prevent damage to goods during transportation. Well-packaged ones shield goods from impacts, vibrations, moisture, and other external factors that could harm or spoil the goods in transit.

Space Optimization

Properly packaged pallets help optimize the use of space in cargo compartments of transportation vehicles. This allows for the most efficient loading of cargo, reducing the number of shipments and lowering logistics costs.

Safety of Personnel and Equipment

Proper packaging ensures the safety of personnel and equipment during loading, unloading, and cargo movement operations. Well-packaged pallets prevent goods from falling or shifting and provide a stable base for forklifts and other machinery to operate safely.

Simplification of Inventory and Tracking

Proper packaging also simplifies the process of inventory and cargo tracking. Well-packaged pallets facilitate access to goods, making it easier to read barcodes and markings, allowing for quick and accurate determination of the whereabouts and condition of goods.

Overall, proper packaging is an integral part of an effective logistical strategy. It helps ensure the safety, efficiency, and reliability of cargo transportation, ultimately contributing to improved productivity and competitiveness of businesses.

Check out why Packaging Companies are Investing in Kodak’s CTP Innovation.

Issues in Pallet Delivery and Their Solutions

Various issues can arise during the delivery, slowing down the process, affecting the condition of the cargo, and increasing operational costs.

Cargo Damage

One of the main issues during the delivery is cargo damage due to improper handling or packaging. To address this issue, proper cargo packaging is necessary, using high-quality packaging materials and training personnel in proper cargo handling methods.

Pallet Loss

During transportation, they can be lost or stolen, leading to additional expenses and delays in deliveries. To prevent its loss, tracking, and control systems need to be implemented, such as barcodes, RFID tags, or GPS trackers, to track their location at all stages of the logistical chain.

Compatibility Issues

Sometimes they may be incompatible with equipment in warehouses or transportation vehicles, which can slow down the loading and unloading process. To address this issue, standard-sized and shaped pallets should be chosen, meeting the requirements of the equipment used in warehouses or transportation vehicles.

Weight Restriction Problems

In some cases, they may exceed the allowable weight limits for transportation vehicles, leading to fines or delivery delays. To address this issue, careful planning of loading is necessary, considering the weight of each cargo and the vehicle’s limitations, as well as using lightweight where possible.

Cargo Handling Issues

Improper cargo handling can lead to damage or loss during transportation. To address this issue, personnel need to be trained in proper cargo handling methods, using appropriate equipment and tools for loading and unloading cargo, and strictly adhering to safety rules and quality standards.

Future Trends in Pallet Shipping

The future of their shipping promises a range of innovations and changes aimed at improving efficiency, sustainability, and automation of logistical processes.

Use of New Materials

One direction of development in their delivery is the use of new materials, such as biodegradable plastics and composite materials, which have improved strength, durability, and environmental resistance properties.

Modern Tracking Technologies

The implementation of modern tracking technologies, such as IoT (Internet of Things) and blockchain, will allow for more accurate and reliable tracking of their location and condition at all stages of the logistical chain. This will reduce losses and optimize inventory management.

Automated Loading and Unloading Systems

The development of automated loading and unloading systems, including robotic forklifts and conveyors with automatic control systems, will significantly increase the speed and efficiency of cargo handling, reduce labor-intensive operations, and improve work safety.

Smart Pallets

The development of smart pallets with built-in sensors and communication systems will allow for gathering information about the location, temperature, humidity, and other environmental parameters, improving control over the condition of goods and enabling timely response to potential issues.

Environmentally Sustainable Solutions

The development of environmentally sustainable solutions, such as pallet reuse and recycling, the use of biodegradable materials, and the reduction of harmful emissions in production and transportation, will contribute to reducing the negative impact on the environment.

Overall, the future of their delivery promises a range of innovations and improvements that will enhance the efficiency, safety, and sustainability of logistical processes, ultimately leading to improved customer service quality and business competitiveness.